To meet the growing demand for boron and zinc in fertilization programs, U.S. Borax recently launched

Anhybor® and

Zincubor® to provide solutions to both the zinc and boron deficiency challenges producers face. Both micronutrients become a limiting factor for crop production, and as producers are learning, both zinc and boron are essential in reaching a crops’ yield potential.

Around the world, both nutrients have been studied extensively, and while many products have been created to meet these challenges, the U.S. Borax portfolio is one of the most comprehensive in terms of concentration and application.

Anhybor and

Zincubor broaden the reach of the solutions U.S. Borax provides producers.

Anhybor for manufacturers

Made for fertilizer manufacturers,

Anhybor is a versatile product that offers two modes of application:

- Boron-enriched compound fertilizer

- Coating on different fertilizer products, such as NPK blends

The product is 100% water-soluble, but does not rehydrate under normal storage conditions.

Anhybor can be handled in bulk.

Anhybor brings value to the fertilizer manufacturing process when it is added before granulation or compaction when making compound fertilizers. Its high boron content is an advantage when make compound fertilizers since less material is needed to achieve the target boron content. The absence of structural water in the chemical composition of

Anhybor makes it easier to use in making compound fertilizers.

Anhybor Fine is a fertilizer manufacturer’s ideal solution to impregnate NPK fertilizers with boron due to the product’s small particle size and excellent coatability. Coating or impregnating fertilizer offers both fertilizer manufacturers and retailers the flexibility to adjust boron rates based on cropping system. U.S. Borax recommends the use of a binder material during the coating process.

Anhybor is versatile, and depending on the grade can be used for many different application types, such as:

- Micronutrient coating: Anhybor Fine is designed to coat granular and compacted fertilizers giving flexibility on the micronutrient rate and assuring an even distribution in the field

- Compound fertilizer: Anhybor can be used as a raw material to produce compound or fortified fertilizers

- Direct soil application: Depending upon the cropping system, Anhybor can be soil applied via fertilizer mixture

Zincubor supplies zinc and boron

Another micronutrient deficiency solution for the fertilizer manufacturing industry,

Zincubor brings together both boron and zinc in one product.

The two-in-one product offers a perfect 2:1 zinc-to-boron ratio to meet the exact zinc and boron demands of most crops. Like

Anhybor,

Zincubor offers several different application opportunities:

- Micronutrient coating: Zincubor is designed to coat granular/compacted fertilizers giving flexibility on the micronutrient rate and assuring an even distribution in the field. U.S. Borax recommends the use of a binder material during the coating process.

- Compound fertilizer: Zincubor can be used as a raw material to produce compound or fortified fertilizers

- Direct soil application: Depending upon the cropping system, Zincubor can be applied directly to soil as a standalone application

- Suspension fertilizer: Zincubor can be used as a raw material to produce suspensions

The proof is in the performance

A solution is only a solution if it works. That’s why we have extensively tested the performance, stability, and efficacy of

Anhybor and

Zincubor.

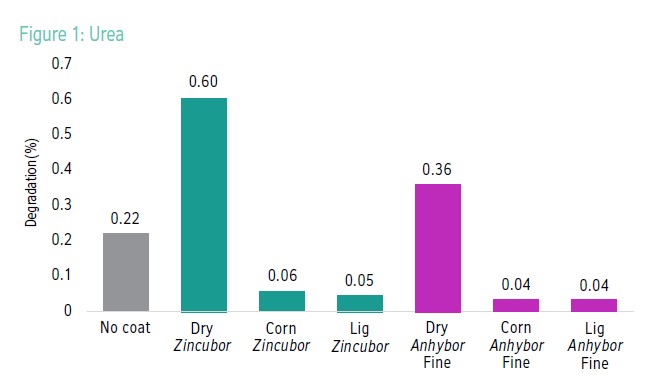

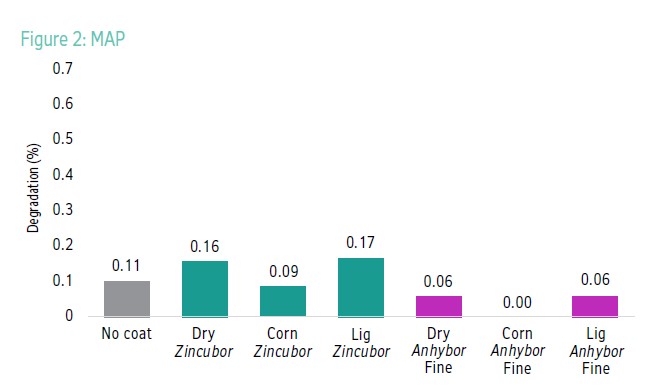

Fertilizer coating efficacy is gauged on the ability to “stick” to fertilizer granules. Dust is the bane of the fertilizer industry, impeding performance in the fertilizer manufacturing facility, in the field, and in product performance. Both

Anhybor Fine and

Zincubor, designed to coat NPK fertilizers, have undergone rigorous performance testing by the International Fertilizer Development Center (IFDC) on urea, MAP, and DAP.

To analyze critical relative humidity (CRH) and abrasion resistance, both products were tested as dry mix, using no binder, and with the aid of two binders: Corn syrup and lignosulfonate. Both

Anhybor Fine and

Zincubor rates on substrates delivered 1kg B/ha (0.9 lb B/acre) when applying urea at a rate of 150 kg N/ha (134 lbs N/acre) and MAP/DAP at a rate of 80 kg P

2O

5/ha (71 lbs P

2O

5/acre).

Testing concluded that CRH did not change for urea, MAP, or DAP—regardless of coating material and binder material, or lack thereof. Abrasion resistance results were also positive, proving that both

Anhybor Fine and

Zincubor coated urea, MAP, and DAP well, even under the presence of “problem simulating” conditions. For example, the addition of dry products intended to show the degradation of urea and the resulting formation of dust. The addition of the binders, however, increased coatability significantly, rendering the dust moot. Testing also found that a dry mix of MAP with

Anhybor Fine generated less dust (from degradation) than uncoated MAP. The use of additional binders improved MAP coating further.

These promising performance test results combined with the flexibility both

Anhybor and

Zincubor afford distributors and retailers proves both products to be an excellent coating option for NPK fertilizers.

Want to learn more?

Our

agronomists and regional sales representatives are ready to answer your questions about the two newest products in our portfolio.

Resources